Introduction

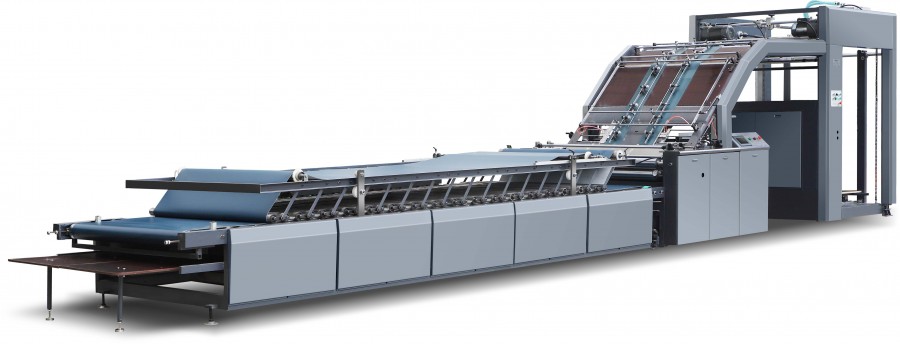

This machine used for laminating cardboard with A/B/C/D/E/F flute or single, double & triple wall corrugated board & 450-700g/m²Grey board.

PLC control system and frequency converter adopt Schneider electrical,adjust the relevant parameters automatically according to the paper size .control is stable and accurate.

Automatic feed top sheet and bottom sheet,and pneumatic correction mechanism is used for feeding top sheet, feeding bottom sheet adopts servo motor control.

Equipped with automatic oil supply lubrication system.

Technical parameters

|

Model |

GFM-1300Z |

GFM-1450Z |

GFM-1700Z |

|

Max. sheet size(mm) |

1300*1100 |

1450*1100 |

1700*1100 |

|

Min. sheet size(mm) |

400*400 |

400*400 |

400*400 |

|

Max. speed (m/min) |

90 |

90 |

90 |

|

Thickness of top cardboard(g/m²) |

200-450 |

200-450 |

200-450 |

|

Thickness of bottom corrugated board |

A/B/C/D/E/F ≤7mm |

A/B/C/D/E/F ≤7mm |

A/B/C/D/E/F ≤7mm |

|

Laminating precision(mm) |

±1 |

±1 |

±1 |

|

Power (kw) |

15 |

15 |

15 |

|

Weight(kg) |

7000 |

8000 |

9000 |

|

Dimension (cm) |

1420*222*268 |

1420*237*268 |

1420*262*268 |

Characters

1. Servo motor drives the suction belts to send bottom sheet

The bottom sheet feeding is smooth and precise.

2.Four sucking nozzles and four feeding nozzles used

for feeder.

High speed,high efficiency.

3.High performance and excellent quality

Main parts adopt imported parts or domestic famous brands

4.Pneumatic correction mechanism for the top sheet

Ensure the laminating precision and stability.

5.PLC and touch screen control system

Operation is more simple

Packaging & Delivery

Packaging Details:

Export wooden box or steel pallet

Delivery Detail:

Shipped in 30 days after payment