价格:

26.00/KG

品牌:LEXAN

起订:25KG

供应:100000KG

发货:1天内

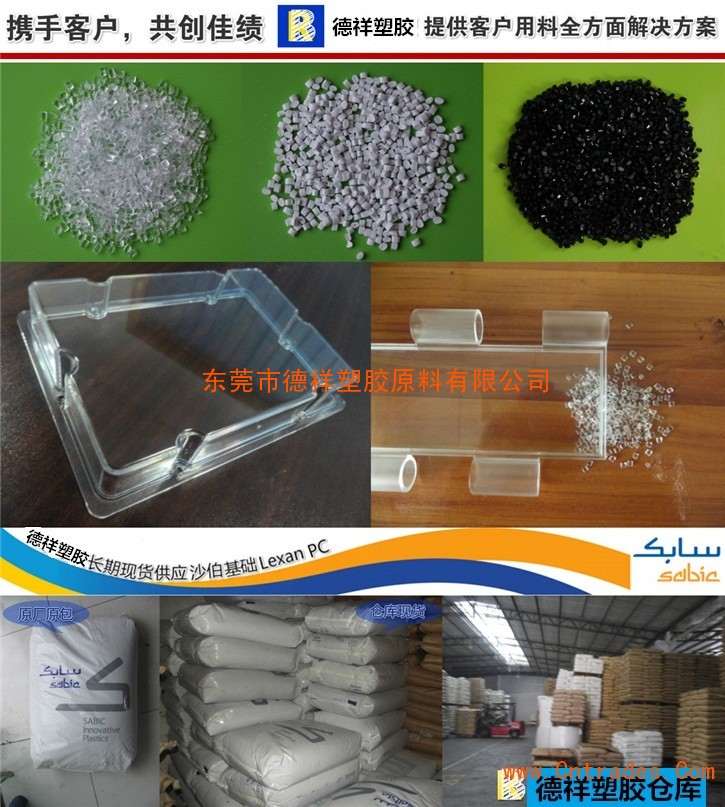

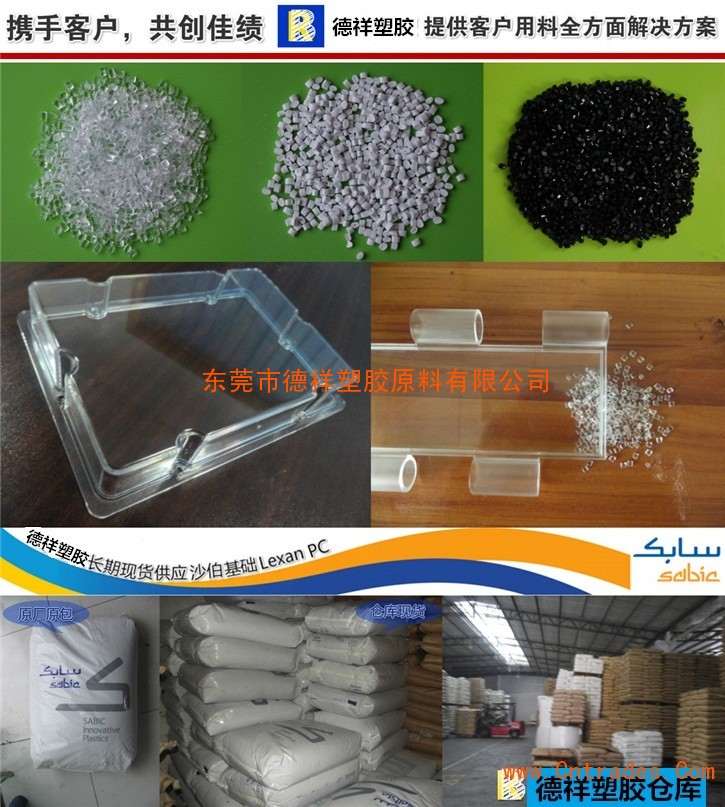

信息标签:LEXAN PC HFD4211美国SABIC厂家直销价格,供应,塑料橡胶,塑料原料

点击这里进行电话呼叫

点击这里QQ咨询

联系时一定要说在【贸易商务资源网】看到的将给您优惠!如果您也想和该公司一样在网站发信息有好排名,点击立即免费注册,发布产品推广。

【特别声明:因塑胶行情每天都会有变更,以上报价可能会与当天实际报价有所差异,请用手机或电话直接询价24小时询价直线13420037086或QQ363743799】

本公司原料25公斤起订,批量可折扣,款到发货或货到付款,珠三角一天内到达,国内各地3-4天到货.

特别声明:因塑胶行情每天都会有变更,页面上有些报价可能会与当天实际报价有所差异,请用手机或电话直接询价。感谢您的大力支持。

郑重承诺:本公司所售原料均为原厂原包装正牌料,杜绝一切副牌料,水口料以次充好。

运费说明:

★ 支持物流,快递和货运,支持现金,银行转账。

★ 本司原料低于500KG,不承担运费,订货500KG以上珠三角地区可送货上门,省外客户物流,快递或货运,不便之处敬请谅解!

★ 选用物流或者快递的买家,请先确认当地是否有该物流或快递的营业网点。

★ 原料到厂后,请不要拆外包装,应先仔细检查原料的外包装是否完好及原料型号是否与您所订购原料型号相匹配。

★ 货物送达后,请当面检查,若物流过程中出现大量包装损坏及原料外漏的,请让物流人员出具证明并保存,并立即与我们联系。

★ 我们承诺期限内发货,但对承运人效率无法作出保证,如果物流快递超出3天,货运超出5天,请联络我们协助查询。

★ 买家也可以根据交易状态中填写的单号信息,自行联系承运方,以便**时间获知详细信息。

★ 本公司原料售后的注塑加工由客户负责,如需帮助,我公司工程部将竭尽所能与您共同协商处理

LEXAN ™ Resin HFD4211

|

|

|

|

|

Americas: COMMERCIAL |

| |

| LEXAN HFD4211 is a 10% glass filled, injection moldable grade designed for high flow and superior surface appearance. Internal mold release. |

| |

| TYPICAL PROPERTIES (1) |

| MECHANICAL |

Value |

Unit |

Standard |

| Tensile Stress, yld, Type I, 5 mm/min |

610 |

kgf/cm² |

ASTM D 638 |

| Tensile Stress, brk, Type I, 5 mm/min |

460 |

kgf/cm² |

ASTM D 638 |

| Tensile Strain, yld, Type I, 5 mm/min |

3.1 |

% |

ASTM D 638 |

| Tensile Modulus, 5 mm/min |

42000 |

kgf/cm² |

ASTM D 638 |

| Flexural Stress, yld, 1.3 mm/min, 50 mm span |

1040 |

kgf/cm² |

ASTM D 790 |

| Flexural Modulus, 1.3 mm/min, 50 mm span |

37600 |

kgf/cm² |

ASTM D 790 |

| Tensile Stress, yield, 5 mm/min |

68 |

MPa |

ISO 527 |

| Tensile Stress, break, 5 mm/min |

59 |

MPa |

ISO 527 |

| Tensile Strain, yield, 5 mm/min |

2.7 |

% |

ISO 527 |

| Tensile Strain, break, 5 mm/min |

3.2 |

% |

ISO 527 |

| IMPACT |

Value |

Unit |

Standard |

| Izod Impact, unnotched, 23°C |

128 |

cm-kgf/cm |

ASTM D 4812 |

| Izod Impact, notched, 23°C |

12 |

cm-kgf/cm |

ASTM D 256 |

| Instrumented Impact Total Energy, 23°C |

509 |

cm-kgf |

ASTM D 3763 |

| Izod Impact, unnotched 80*10*3 +23°C |

64 |

kJ/m² |

ISO 180/1U |

| Izod Impact, unnotched 80*10*3 -30°C |

60 |

kJ/m² |

ISO 180/1U |

| Izod Impact, notched 80*10*3 +23°C |

6 |

kJ/m² |

ISO 180/1A |

| Izod Impact, notched 80*10*3 -30°C |

6 |

kJ/m² |

ISO 180/1A |

| Charpy 23°C, V-notch Edgew 80*10*3 sp=62mm |

6 |

kJ/m² |

ISO 179/1eA |

| Charpy -30°C, V-notch Edgew 80*10*3 sp=62mm |

7 |

kJ/m² |

ISO 179/1eA |

| Charpy 23°C, Unnotch Edgew 80*10*3 sp=62mm |

75 |

kJ/m² |

ISO 179/1eU |

| Charpy -30°C, Unnotch Edgew 80*10*3 sp=62mm |

81 |

kJ/m² |

ISO 179/1eU |

| THERMAL |

Value |

Unit |

Standard |

| HDT, 0.45 MPa, 3.2 mm, unannealed |

129 |

°C |

ASTM D 648 |

| HDT, 1.82 MPa, 3.2mm, unannealed |

123 |

°C |

ASTM D 648 |

| CTE, -40°C to 40°C, flow |

4.E-05 |

1/°C |

ASTM E 831 |

| CTE, -40°C to 40°C, xflow |

8.E-05 |

1/°C |

ASTM E 831 |

| CTE, 23°C to 80°C, flow |

4.E-05 |

1/°C |

ISO 11359-2 |

| CTE, 23°C to 80°C, xflow |

8.E-05 |

1/°C |

ISO 11359-2 |

| Ball Pressure Test, 125°C +/- 2°C |

PASSES |

- |

IEC 60695-10-2 |

| Vicat Softening Temp, Rate B/120 |

141 |

°C |

ISO 306 |

| HDT/Af, 1.8 MPa Flatw 80*10*4 sp=64mm |

126 |

°C |

ISO 75/Af |

| Relative Temp Index, Elec |

80 |

°C |

UL 746B |

| Relative Temp Index, Mech w/impact |

80 |

°C |

UL 746B |

| Relative Temp Index, Mech w/o impact |

80 |

°C |

UL 746B |

| PHYSICAL |

Value |

Unit |

Standard |

| Specific Gravity |

1.27 |

- |

ASTM D 792 |

| Mold Shrinkage, flow, 3.2 mm (5) |

0.2 - 0.4 |

% |

SABIC Method |

| Mold Shrinkage, xflow, 3.2 mm (5) |

0.2 - 0.4 |

% |

SABIC Method |

| Melt Flow Rate, 300°C/1.2 kgf |

18 |

g/10 min |

ASTM D 1238 |

| Density |

1.25 |

g/cm³ |

ISO 1183 |

| Water Absorption, (23°C/sat) |

0.3 |

% |

ISO 62 |

| Moisture Absorption (23°C / 50% RH) |

0.12 |

% |

ISO 62 |

| Melt Volume Rate, MVR at 300°C/1.2 kg |

12 |

cm³/10 min |

ISO 1133 |

| FLAME CHARACTERISTICS |

Value |

Unit |

Standard |

| UL Recognized, 94HB Flame Class Rating (3) |

0.3 |

mm |

UL 94 |

| Glow Wire Flammability Index 960°C, passes at |

1 |

mm |

IEC 60695-2-12 |

| Glow Wire Ignitability Temperature, 1.0 mm |

850 |

°C |

IEC 60695-2-13 |

| Source GMD, last updated:2012/04/27 |

| Parameter |

| Injection Molding |

Value |

Unit |

| Drying Temperature |

120 |

°C |

| Drying Time |

3 - 4 |

hrs |

| Drying Time (Cumulative) |

48 |

hrs |

| Maximum Moisture Content |

0.02 |

% |

| Melt Temperature |

290 - 310 |

°C |

| Nozzle Temperature |

280 - 305 |

°C |

| Front - Zone 3 Temperature |

290 - 310 |

°C |

| Middle - Zone 2 Temperature |

275 - 300 |

°C |

| Rear - Zone 1 Temperature |

265 - 290 |

°C |

| Mold Temperature |

70 - 95 |

°C |

| Back Pressure |

0.3 - 0.7 |

MPa |

| Screw Speed |

40 - 70 |

rpm |

| Shot to Cylinder Size |

40 - 60 |

% |

| Vent Depth |

0.025 - 0.076 |

mm

|